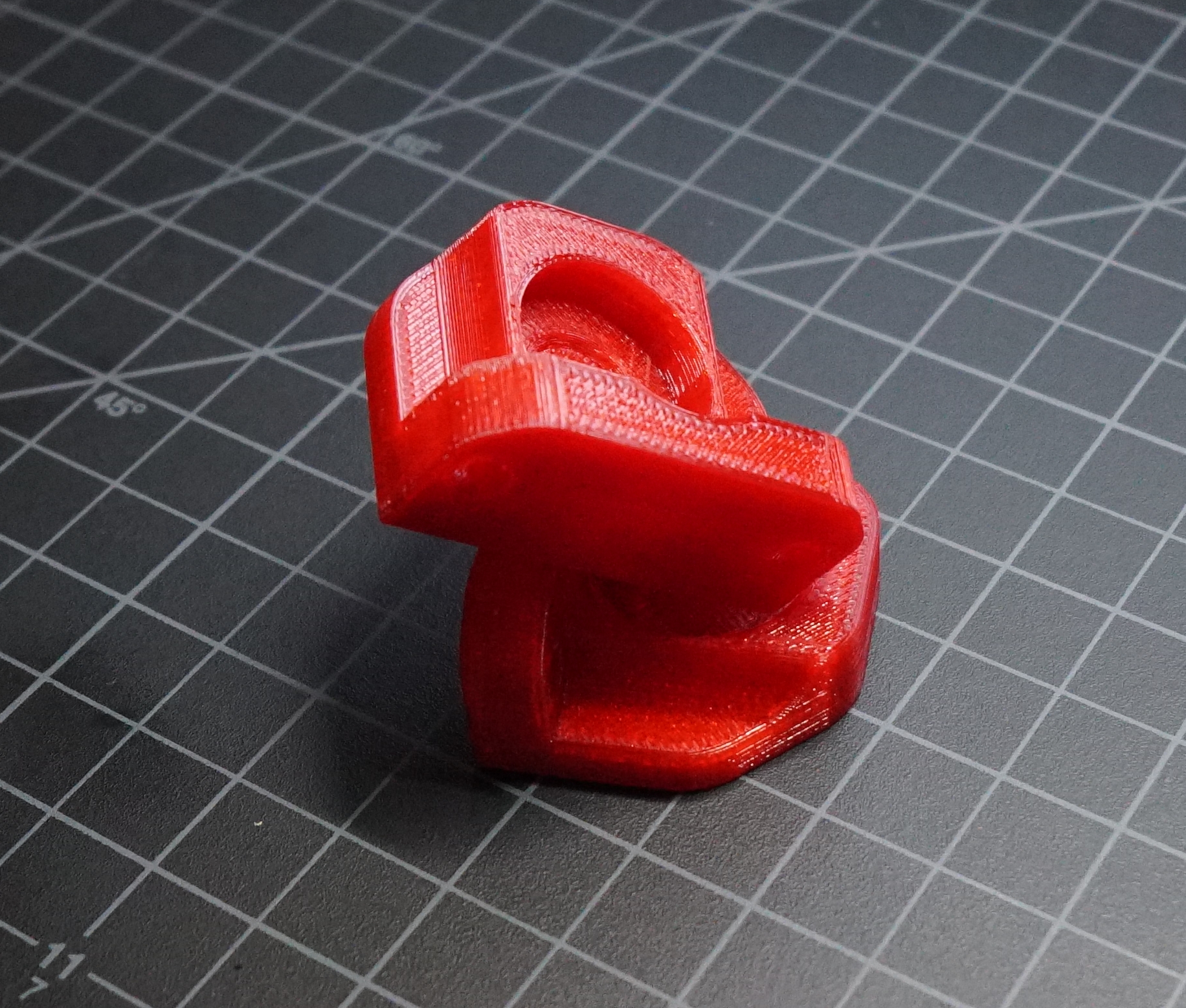

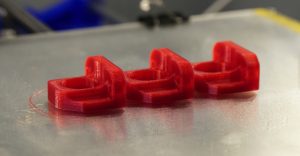

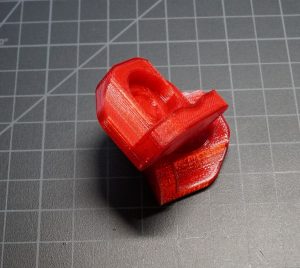

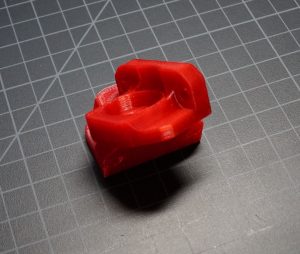

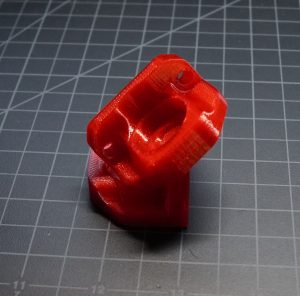

Captured Bearing Holders

It may not come out in the pictures, but these parts are far better than the first print. The smoothness around the curved nose is very good and consistent. I also didn’t get the big blob collecting on the hotend that fell off mid-print and nearly wrecked it like on the first print. Some plastic did collect on the hotend though, so I’ll continue to tweak the extrusion multiplier to see if I can get that cleaned up.

See the settings in RED below for those that were changed between prints. The primary impetus for these changes was to decrease print time without affecting overall print quality and strength.

Print Settings

- Printer: Wilson2 (customized)

- Filament: Atomic Filament PETG Ruby Red Translucent

- Slicer: Simplify3D

- Hotend Temperature: 240ºC

- Bed Temperature: 75ºC (first layer), 65ºC (all other layers)

- Layer Height: 0.15mm

- Solid Bottom Layers: 3

- Solid Top Layers: 4

- Perimeter Shells: 2

- Infill: 100% Rectilinear @ 100% width

- Sparse Infill: Every 2 Layers

- Print Speed: 50mm/s

If you have any questions or suggestions, let me know in the comments.